Process Production and Classification of Wire Harness

- PRODUCT DETAIL

The first station of wire harness production is the wire cutting process. The accuracy of the cutting process is directly related to the entire production schedule. Once an error occurs, especially the opening size is too short, it will cause all stations to rework, which will take time and effort to affect production efficiency.

The second station after wire cutting is the crimping process. Determine the crimping parameters according to the terminal type required by the drawing, make the crimping operation manual, indicate on the process documents for special requirements, and train the operators.

Then comes the pre-installation process. First, we must prepare the pre-assembly process operation manual. In order to improve the overall assembly efficiency, the complex wiring harness must be equipped with pre-assembly stations. If the pre-installed part is less assembled or the wire path of the assembly is unreasonable, it will increase the workload of the general assembler.

The final step is the final assembly process. According to the assembly platform designed by the product development department, design tooling equipment and material box specifications. And paste the serial numbers of all assembly sheaths and accessories on the material box to improve assembly efficiency.

The electronic technology content and quality of automobile wiring harness in the car has gradually become an important index for evaluating automobile performance. Automobile manufacturers should pay particular attention to the selection of wiring harnesses, and it is also necessary to understand the process and production of automotive wiring harnesses.

According to the different service methods, it is divided into loss-making wiring harness and waiting-making wiring harness (see random service system);

According to the number of load sources of the service, it is divided into infinite load source wiring harness and limited load source wiring harness.

In the telecommunication system, the equipment directly used for communication between users is mostly an unlimited load source loss system full utilization link system. The equipment used to control the connection process of communication equipment is mostly an infinite load source waiting system full utilization system.

When the number of load sources is not very large relative to the capacity of the wire harness, a full utilization system or a partial utilization system with limited load sources is generally used.

According to the call behavior of the load source, that is, whether the user makes a new call attempt after the call fails, the wiring harness can be divided into a repeated call system and a non-repeated call system. The actual communication system has repeated calls, and the non-repetitive call system is an approximation of the repeated call system.

1) Full utilization of wire harness. If any service device (trunk or key) in the wiring harness can be used by any load source in the load source group it serves, then such a harness is called a full utilization harness.

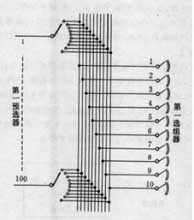

As shown in Figure 2: Step-by-step switchboard has 100 first load source groups, and the 10 outgoing lines of its arcs are correspondingly multiplexed to 10 first group selectors to form a full utilization wire harness. Any service device in the circle can be used by any load source in the load source group it serves.

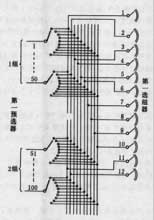

2) Partial utilization of wire harness. If any load source in the load source group can only use part of the service functions in the wire harness, such a wire harness is called a partial utilization harness. The partial utilization harness divides the load source into several sub-groups, and performs multiple connection between the outlet lines of the load group. This structure can be described by the example shown in the figure below.

The above figure divides 100 load sources (the first preselector in the step-by-step switch) into two load source groups, and the first and second steps of the first group are correspondingly multiplexed to the first group selector 1 and 2. The first and second steps of the second group are correspondingly multiplexed to the first group selectors 11 and 12. The 3rd~10th outlets of the two groups are all correspondingly multiplexed to the first group selector 3~10. It can be seen from the figure that the first group selector 1, 2 (service equipment 1, 2) can only be used by the first group load source. The first group selector 11, 12 can only be used by the second subgroup of load sources. The 3-10 of the first selection group can be used for the entire load source group.

The traffic load capacity of the partial utilization harness is lower than the full utilization harness under the same harness capacity. Its traffic load capacity or call loss rate is related to the utilization and the method of reconnection by product. Under the same condition that the capacity of the wire harness and the call loss rate are the same, a good multiplex structure can improve the load capacity of the wire harness. The greater the utilization, the closer the efficiency of the harness is to the full utilization harness.

The second station after wire cutting is the crimping process. Determine the crimping parameters according to the terminal type required by the drawing, make the crimping operation manual, indicate on the process documents for special requirements, and train the operators.

Then comes the pre-installation process. First, we must prepare the pre-assembly process operation manual. In order to improve the overall assembly efficiency, the complex wiring harness must be equipped with pre-assembly stations. If the pre-installed part is less assembled or the wire path of the assembly is unreasonable, it will increase the workload of the general assembler.

The final step is the final assembly process. According to the assembly platform designed by the product development department, design tooling equipment and material box specifications. And paste the serial numbers of all assembly sheaths and accessories on the material box to improve assembly efficiency.

The electronic technology content and quality of automobile wiring harness in the car has gradually become an important index for evaluating automobile performance. Automobile manufacturers should pay particular attention to the selection of wiring harnesses, and it is also necessary to understand the process and production of automotive wiring harnesses.

Harness classification

According to different structures, it is divided into full utilization wire harness, partial utilization wire harness and link system;According to the different service methods, it is divided into loss-making wiring harness and waiting-making wiring harness (see random service system);

According to the number of load sources of the service, it is divided into infinite load source wiring harness and limited load source wiring harness.

In the telecommunication system, the equipment directly used for communication between users is mostly an unlimited load source loss system full utilization link system. The equipment used to control the connection process of communication equipment is mostly an infinite load source waiting system full utilization system.

When the number of load sources is not very large relative to the capacity of the wire harness, a full utilization system or a partial utilization system with limited load sources is generally used.

According to the call behavior of the load source, that is, whether the user makes a new call attempt after the call fails, the wiring harness can be divided into a repeated call system and a non-repeated call system. The actual communication system has repeated calls, and the non-repetitive call system is an approximation of the repeated call system.

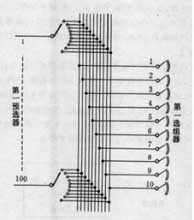

1) Full utilization of wire harness. If any service device (trunk or key) in the wiring harness can be used by any load source in the load source group it serves, then such a harness is called a full utilization harness.

As shown in Figure 2: Step-by-step switchboard has 100 first load source groups, and the 10 outgoing lines of its arcs are correspondingly multiplexed to 10 first group selectors to form a full utilization wire harness. Any service device in the circle can be used by any load source in the load source group it serves.

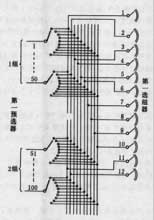

2) Partial utilization of wire harness. If any load source in the load source group can only use part of the service functions in the wire harness, such a wire harness is called a partial utilization harness. The partial utilization harness divides the load source into several sub-groups, and performs multiple connection between the outlet lines of the load group. This structure can be described by the example shown in the figure below.

The above figure divides 100 load sources (the first preselector in the step-by-step switch) into two load source groups, and the first and second steps of the first group are correspondingly multiplexed to the first group selector 1 and 2. The first and second steps of the second group are correspondingly multiplexed to the first group selectors 11 and 12. The 3rd~10th outlets of the two groups are all correspondingly multiplexed to the first group selector 3~10. It can be seen from the figure that the first group selector 1, 2 (service equipment 1, 2) can only be used by the first group load source. The first group selector 11, 12 can only be used by the second subgroup of load sources. The 3-10 of the first selection group can be used for the entire load source group.

The traffic load capacity of the partial utilization harness is lower than the full utilization harness under the same harness capacity. Its traffic load capacity or call loss rate is related to the utilization and the method of reconnection by product. Under the same condition that the capacity of the wire harness and the call loss rate are the same, a good multiplex structure can improve the load capacity of the wire harness. The greater the utilization, the closer the efficiency of the harness is to the full utilization harness.