What is a connector?

Connector refers to a direct connection device between two independent parts. For example, hooks can also be used to connect. In a narrow sense, it refers to the direct coupling device between the end faces of two rotating parts (shafts). The connector can be used to connect or cut off the power of the engine. Connectors can basically be divided into three types: non-separable, detachable and safe. By a connector web, two side webs connecting pins symmetrically disposed, and the other side relative to the connector pin position of the mounting means intermediate linker composed.

Use of circuit line connectors

In automotive circuits, there are many wires that need to be connected. In order to facilitate maintenance, some connecting parts must be able to be disconnected and combined smoothly. The connection parts of imported automobile circuits are all line connectors made of insulating plastic. The connector is divided into two parts, one is called a male terminal, and there are several plugs inside; The other part is called a female terminal, which contains several sockets. Guide grooves are formed on the two terminals. Align and insert the guide grooves on the terminal to ensure the correct connection of the connector. In order to prevent the connector from falling off during work, insert cards are installed on the two terminals. After the connector is inserted tightly, inserting the card will lock the two terminals.

When disassembling the coupling, snap-in tongue is pushed down, the force to separate the two terminals. When checking the voltage or continuity of the circuit, it is not necessary to disconnect the connector, just insert the two probes of a multimeter into the wire hole at the end of the connector for inspection. During the repair, if you need to replace the wire or remove the connector plug, you should first separate the two terminals, insert the connector with a small screwdriver, pry the wire locking flange, and pull the wire out from the back. When installing, push the wire end until it is locked firmly, and then pull the wire backward to confirm whether it is locked.

When disassembling the connector, push down the circlip to separate the two terminals forcefully. When checking the voltage or continuity of the circuit, it is not necessary to disconnect the connector, just insert the two probes of a multimeter into the wire hole at the end of the connector for inspection. When repairing, if you need to replace the wire or remove the connector plug, you should first separate the two terminals, insert the connector with a small screwdriver, pry the wire locking flange, and pull the wire out from the back. When installing, push the wire end until it is locked firmly, and then pull the wire backward to confirm whether it is locked.

Connector design

The device connecting the extrusion mold and the extruder is called a connector. The structure of the connector is diverse, but most of them are connected by clamps and hinged screws. According to different extruder specifications and production methods, commonly used connectors have the following three structural forms.

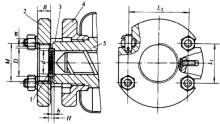

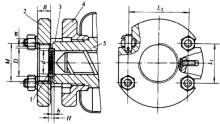

Threaded connector

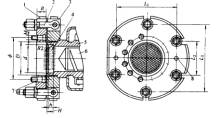

Connectors of this structure are mostly used in small and medium-sized extruders. As shown in the figure below, connect the outer side of the extrusion mold with threads and flanges to form a whole, and then fasten the head flange 2 to the barrel flange 4 with hinge screws 3 to form a complete connector system. The concentricity of this connection method is based on the grid axis to achieve the requirement of coaxial concentricity. The end surface of the grid should have a pressing table to prevent leakage.

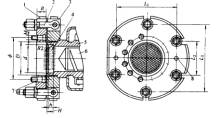

Screw connector

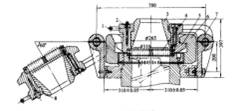

This structure is mostly used in large and medium-sized extruders. As shown in the figure below, fix the head flange 1 on the end face of the extrusion mold with 12 cylindrical head hexagon socket screws 7. Because the outer circular surface of the start end of the extrusion mold and the inner hole (usually a reference hole) of the flange 1 of the injection molding machine head constitute a transitional fit. The pin 8 is used to position the injection molding machine head flange 1 and the injection molding machine barrel flange 3, and then the hinge screw 2 is used to lock it, thereby forming a structure with screw connection as the main body. It can be seen from this structure that its concentricity can be fully guaranteed.

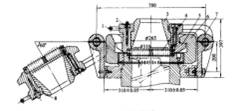

Clamp connector

As shown in the figure below, the clamp locking ring 6 is driven to rotate by hydraulic pressure to loosen the threaded part. When it rotates to the center of the grooved part and the convex part of the front compression ring 3, the front compression ring 5 can rotate around the axis on the hinge seat 7 to exit the clamp locking ring 6. Move the machine head to the right to clean it. Then quickly replace the cleaned machine head on the left side, make the protrusion of the front compression ring 5 align with the groove of the locking ring 6, and then drive the locking ring 6 by hydraulic pressure until it is re-locked.

Connector refers to a direct connection device between two independent parts. For example, hooks can also be used to connect. In a narrow sense, it refers to the direct coupling device between the end faces of two rotating parts (shafts). The connector can be used to connect or cut off the power of the engine. Connectors can basically be divided into three types: non-separable, detachable and safe. By a connector web, two side webs connecting pins symmetrically disposed, and the other side relative to the connector pin position of the mounting means intermediate linker composed.

Use of circuit line connectors

In automotive circuits, there are many wires that need to be connected. In order to facilitate maintenance, some connecting parts must be able to be disconnected and combined smoothly. The connection parts of imported automobile circuits are all line connectors made of insulating plastic. The connector is divided into two parts, one is called a male terminal, and there are several plugs inside; The other part is called a female terminal, which contains several sockets. Guide grooves are formed on the two terminals. Align and insert the guide grooves on the terminal to ensure the correct connection of the connector. In order to prevent the connector from falling off during work, insert cards are installed on the two terminals. After the connector is inserted tightly, inserting the card will lock the two terminals.

When disassembling the coupling, snap-in tongue is pushed down, the force to separate the two terminals. When checking the voltage or continuity of the circuit, it is not necessary to disconnect the connector, just insert the two probes of a multimeter into the wire hole at the end of the connector for inspection. During the repair, if you need to replace the wire or remove the connector plug, you should first separate the two terminals, insert the connector with a small screwdriver, pry the wire locking flange, and pull the wire out from the back. When installing, push the wire end until it is locked firmly, and then pull the wire backward to confirm whether it is locked.

When disassembling the connector, push down the circlip to separate the two terminals forcefully. When checking the voltage or continuity of the circuit, it is not necessary to disconnect the connector, just insert the two probes of a multimeter into the wire hole at the end of the connector for inspection. When repairing, if you need to replace the wire or remove the connector plug, you should first separate the two terminals, insert the connector with a small screwdriver, pry the wire locking flange, and pull the wire out from the back. When installing, push the wire end until it is locked firmly, and then pull the wire backward to confirm whether it is locked.

Connector design

The device connecting the extrusion mold and the extruder is called a connector. The structure of the connector is diverse, but most of them are connected by clamps and hinged screws. According to different extruder specifications and production methods, commonly used connectors have the following three structural forms.

Threaded connector

Connectors of this structure are mostly used in small and medium-sized extruders. As shown in the figure below, connect the outer side of the extrusion mold with threads and flanges to form a whole, and then fasten the head flange 2 to the barrel flange 4 with hinge screws 3 to form a complete connector system. The concentricity of this connection method is based on the grid axis to achieve the requirement of coaxial concentricity. The end surface of the grid should have a pressing table to prevent leakage.

Screw connector

This structure is mostly used in large and medium-sized extruders. As shown in the figure below, fix the head flange 1 on the end face of the extrusion mold with 12 cylindrical head hexagon socket screws 7. Because the outer circular surface of the start end of the extrusion mold and the inner hole (usually a reference hole) of the flange 1 of the injection molding machine head constitute a transitional fit. The pin 8 is used to position the injection molding machine head flange 1 and the injection molding machine barrel flange 3, and then the hinge screw 2 is used to lock it, thereby forming a structure with screw connection as the main body. It can be seen from this structure that its concentricity can be fully guaranteed.

Clamp connector

As shown in the figure below, the clamp locking ring 6 is driven to rotate by hydraulic pressure to loosen the threaded part. When it rotates to the center of the grooved part and the convex part of the front compression ring 3, the front compression ring 5 can rotate around the axis on the hinge seat 7 to exit the clamp locking ring 6. Move the machine head to the right to clean it. Then quickly replace the cleaned machine head on the left side, make the protrusion of the front compression ring 5 align with the groove of the locking ring 6, and then drive the locking ring 6 by hydraulic pressure until it is re-locked.

PREVIOUS:NONE

NEXT:China Connector Manufacturer

NEXT:China Connector Manufacturer