4 precautions for car wiring harness layout

With the continuous improvement of modern automobile safety, comfort and environmental protection requirements, the number of circuits and power consumption on automobiles has increased significantly. Therefore, how to arrange a large number of wiring harnesses more effectively and reasonably in a limited car space has become a problem faced by the automobile manufacturing industry. This article focuses on the layout of automotive wiring harnesses and gives an overview of the precautions for automotive wiring harness layout.

I. The wiring harness fixing points should be arranged reasonably and fixed reliably

(1) According to the actual installation position of the wire harness on the whole vehicle, in order to avoid sagging and displacement of the wire harness, consider the weight of the wire harness, the fixing method and the convenience of the fixing position. The wiring harness must have sufficient and reasonable fixing points and fixing methods for fixing.

(2) Set fixed points according to the direction of the wiring harness and the specific shape of the body. The distance between two fixed points on a straight line without a fulcrum is generally not more than 300mm; A fixed point can be set at the obtuse corner position; Two fixed points need to be set at the right-angle inflection point; Avoid sharp corners during wiring harness layout.

(3) Select the type and size of the fixed buckle according to the shape and outer diameter of the wire harness, and meet the needs of bearing the weight of the wire harness.

(4) Consider setting a fixed point at the position of the connector connected to other wiring harnesses and electrical devices, and a suitable position not greater than 120mm in front of the connector.

(5) Consider setting a fixed point on the trunk line at the position of the fulcrum, and the distance from the fixed point to the fulcrum is not more than 100mm.

(6) In the installation direction of the fixed buckle, there must be enough space to facilitate the installation and removal of the buckle.

II. Neat appearance, bundled configuration

(1) The wiring harness should be arranged along the edges and along the groove (the wiring groove designed on the car body) to avoid direct pressure on the wiring harness. No cable harnesses shall be exposed in the cab; Where the wire harness can be observed, For example, in the engine room, set eye-catching attraction points or eye-catching colors, and the wiring harness installed here is not protruding or conspicuous.

(4) Consider setting a fixed point at the position of the connector connected to other wiring harnesses and electrical devices, and a suitable position not greater than 120mm in front of the connector.

(5) Consider setting a fixed point on the trunk line at the position of the fulcrum, and the distance from the fixed point to the fulcrum is not more than 100mm.

(6) In the installation direction of the fixed buckle, there must be enough space to facilitate the installation and removal of the buckle.

II. Neat appearance, bundled configuration

(1) The wiring harness should be arranged along the edges and along the groove (the wiring groove designed on the car body) to avoid direct pressure on the wiring harness. No cable harnesses shall be exposed in the cab; Where the wire harness can be observed, For example, in the engine room, set eye-catching attraction points or eye-catching colors, and the wiring harness installed here is not protruding or conspicuous.

(2) Arrangement in the projection direction, in a horizontal and vertical checkerboard arrangement, avoiding diagonal arrangement.

(3) The gap with the pipeline is uniform, and the gap with the surrounding parts is reasonable.

III. Harness avoid interference with surrounding parts

(1) Do not directly touch the sharp edges of the body. One, need to leave a gap space. Second, it is necessary to increase protection to prevent the sharp edges of the body from damaging the outer insulation layer of the wiring harness and causing short-circuit accidents;

(2) When installing on vibrating or moving parts, the length should be reserved according to the actual situation. The reserved length is determined according to the vibration amplitude of the component and the maximum movement stroke of the moving part. Ensure that the reserved length can not transmit the vibration on the wire harness or make the wire harness bear the tension. If the wiring harness is subjected to vibration transmission or tension for a long time, it may cause virtual connection between the internal contacts of the wiring harness and the terminals of the connector. Such as: engine wiring harness and engine compartment wiring harness connection.

(3) The gap with the pipeline is uniform, and the gap with the surrounding parts is reasonable.

III. Harness avoid interference with surrounding parts

(1) Do not directly touch the sharp edges of the body. One, need to leave a gap space. Second, it is necessary to increase protection to prevent the sharp edges of the body from damaging the outer insulation layer of the wiring harness and causing short-circuit accidents;

(2) When installing on vibrating or moving parts, the length should be reserved according to the actual situation. The reserved length is determined according to the vibration amplitude of the component and the maximum movement stroke of the moving part. Ensure that the reserved length can not transmit the vibration on the wire harness or make the wire harness bear the tension. If the wiring harness is subjected to vibration transmission or tension for a long time, it may cause virtual connection between the internal contacts of the wiring harness and the terminals of the connector. Such as: engine wiring harness and engine compartment wiring harness connection.

(3) The gap with moving parts should be greater than 25mm, such as the gap between the wire and connecting rod of the wiper motor.

(4) The distance to the exhaust manifold should be greater than 50mm.

(5) The distance from the parts whose temperature is greater than 150°C at the engine is greater than 50mm.

(6) Do not use the same fixed point as the fuel line and brake line.

(7) Do not cross or touch the fuel line and brake line. Especially the wiring harness connection part and the oil circuit connection part, to avoid the line surface damage and short circuit and the oil evaporation density and other conditions to cause fire.

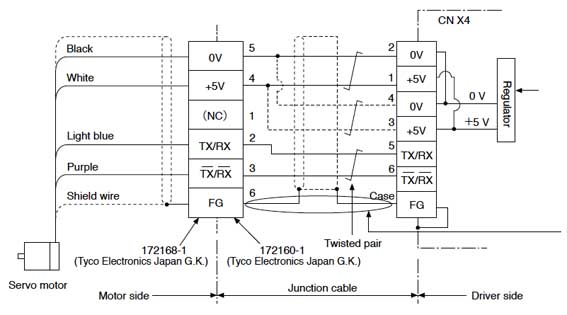

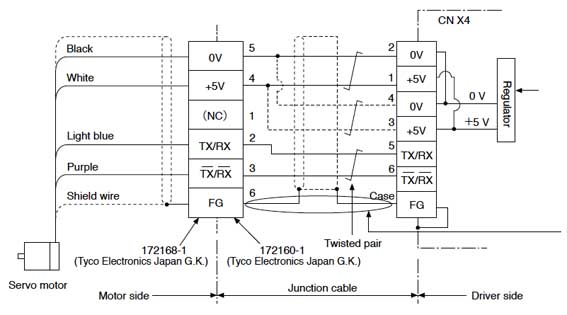

IV. Anti-electromagnetic interference

(1) The audio wiring harness must have anti-electromagnetic interference measures to ensure the signal-to-noise ratio of the collected signals such as the audio system, so that it can work normally.

(4) The distance to the exhaust manifold should be greater than 50mm.

(5) The distance from the parts whose temperature is greater than 150°C at the engine is greater than 50mm.

(6) Do not use the same fixed point as the fuel line and brake line.

(7) Do not cross or touch the fuel line and brake line. Especially the wiring harness connection part and the oil circuit connection part, to avoid the line surface damage and short circuit and the oil evaporation density and other conditions to cause fire.

IV. Anti-electromagnetic interference

(1) The audio wiring harness must have anti-electromagnetic interference measures to ensure the signal-to-noise ratio of the collected signals such as the audio system, so that it can work normally.

(3) Avoid electromagnetic interference sources of parts, such as: arranging some signal lines as far away from the interference source as possible. Such as: electric horns, ignition coils, motors and other remote locations.

(4) The signal power line of the sensor should avoid the power line of high-current parts, and the interval should be greater than 300mm to avoid signal interference.

(5) Arrange electrical appliances reasonably and shorten the length of signal lines.

(6) The grounding wires of some key systems and important systems are arranged in one place separately to avoid interference from other grounding wires. For example, the airbag system, ABS, ECU engine control system and audio system are all implemented in a two-wire system, and the whole system uses a grounding point.

(7) Add shielding and grounding to the electrical appliance shell in the location susceptible to interference.